The Sure-Saf® System has been developed to provide optimal safety using rupture disk (bursting disc) pressure relief technology. The CSI™ rupture disk (bursting disc) combined with the CSR-7RS™ safety head provides accuracy and reliability. This unique partnership ensures the CSI™ disk bursts at or below its certified burst pressure in the event that the disk is installed in the wrong direction or becomes damaged.

The CSI™ rupture disk (bursting disc) uses SafT technology (structural apex forming), the central feature on the disk dome, which enhances accuracy of burst pressure. At its burst pressure, the CSI™ rupture disk (bursting disc) dome reverses and opens by shearing around a circular score line located at the perimeter of the dome. The CSR-7RS™ safety head outlet contains an energy-absorbing hinge that aligns with an unscored portion of the CSI™ disk perimeter that retains the CSI™ disk upon opening, avoiding fragmentation.

Reverse Buckling Disk in Sizes 1" / 25mm ~ 8" / 200mm

Non-Fragmentation Design

Designed for Gas, Liquid, or 2-phase Flow Conditions

Fail Safe: Reversal Safety Ratio <1

Fail Safe: Damage Safety Ratio <1

High Operating Ratio: 90% of Marked Burst Pressure

High Operating Ratio: 95% of Minimum Burst Pressure (ISO & European Codes)

SafT Technology

Vacuum Resistant

Resists Product Accumulation

Static or Cyclic Operating Conditions

Standard 0% Manufacturing Design Range

Optional -5% & -10% Manufacturing Design Range

Should the CSI™ rupture disk (bursting disc) in its CSR-7RS™ safety head be accidentally installed the wrong way, it will burst at or typically below its burst pressure. This "fail-safe" design feature is called the reversal safety ratio. With a value of 1 or less, the CSI™ disk will relieve pressure at a reduced burst pressure should improper installation cause pressure to be applied to the disk's concave side.

Installed in the wrong direction, the CSI™ rupture disk (bursting disc) interacts along its circular score line with stress raising features in the CSR-7RS™ safety head to open at a reduced burst pressure.

If the CSR™ rupture disk (bursting disc) is accidentally damaged, it will relieve pressure by bursting at or typically below its marked burst pressure. This "fail-safe" design feature is called the damage safety ratio. With a value of 1 or less, the CSI™ disk will relieve pressure at a reduced burst pressure if damaged. When the domed structure of the CSI™ rupture disk (bursting disc) is damaged, it will reverse at a reduced pressure and interact along its circular score line with stress raising features in the CSR-7RS™ safety head to open at a reduced burst pressure.

Burst tolerance is the +/- range of pressure over which a rupture disk (bursting disc) can be expected to burst.

Burst tolerance is either +/-5% of burst pressure or +/-2psi (+/-0.138 bar) for disks rated below 40 psi/2.76 bar.

Flow resistance factor "KR" may be used to determine the relieving capacity of a system when using techniques such as those described in Crane Technical Paper No. 410. Individual KR values have been established for both Gas & Liquid service for the CSI™ disk. These are experimentally determined at the BS&B Safety Systems Inc. flow laboratory following ASME procedures and witnessed by ASME representatives. Care must be taken to use the correct value for sizing purposes. When KR values are marked on the CSI™ disk tag, those for gas service are shown as "KRG", and those for liquid service are shown as "KRL". The KRg value is 0.62 and the KRI value is 6.92.

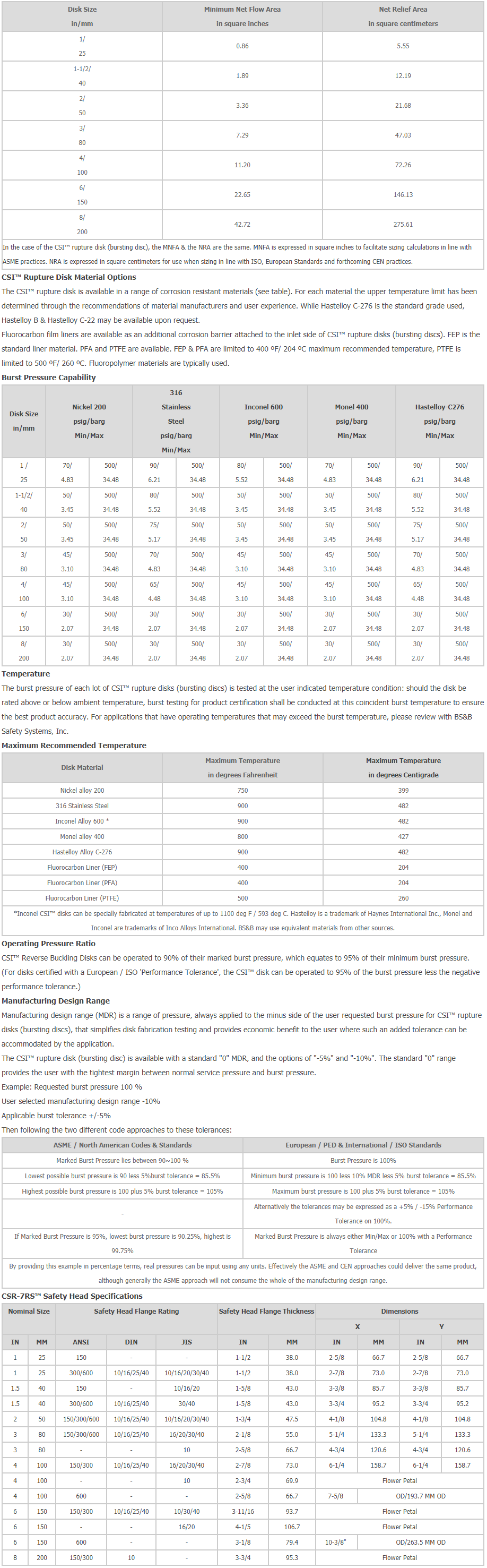

When using KR value for sizing calculations, the nominal pipe size (assuming schedule 40 pipe) of the vent system is used. When using 'coefficient of discharge' sizing techniques, the Minimum Net Flow Area or Net Relief Area of the rupture disk (bursting disc) device is used. This information is shown with the CSR-7RS™ safety head details.

Asymmetric locating pins center the disk in the safety head eliminating disk slippage and ensuring correct installation.

The CSR-7RS™ can be pretorqued in the workshop for exact calibration permitting simple and correct installation.

For further installation assurance, a J-bolt is fitted which mates with a hole drilled in the inlet companion flange.

The CSR-7RS™ fits multiple international flanges ratings including ANSI, DIN, BS and JIS, thus reducing unwanted inventory.

Metal to metal bite-type seal 2 inches and above.

Unique stress raising features in the bore of the CSR-7RS™ interact with the CSI™ disk circular score line to provide a Reversal Safety Ratio & Damage Safety Ratio of 1 or less.

Materials available: 316SS, Carbon Steel, Inconel Alloy 600, Monel Alloy 400 and Hastelloy-C276/Alloy C-276.

Patent Information

CSI™ rupture disk (bursting disc):

Worldwide patents & US 5167337.

US and worldwide patents pending.

CSR-7RS™ safety head:

Worldwide patents and US 4751938 & 5005722.

Products, specifications and all data in this literature are subject to change without notice. Questions regarding product selection and specifications for specific applications should be directed to BS&B Safety Systems, Inc. or BS&B Safety Systems Ltd.

All sales are subject to BS&B Safety Systems, Inc. or BS&B Safety Systems Ltd. standard terms and conditions of sale.

上海市闵行区华宁路200号3幢

737528458

sales@deerxing.net

微信公众号

钉钉企业主页